What is the Best Tool for Breaking up Concrete?

If you have concrete that needs to be broken, there are several types of concrete hammers that might do the job and a number of factors to consider when choosing the right tool. By analyzing the job and having a plan in place, you can save time, effort and money.

There are a few questions to ask that can help:

- How big is the job?

- How accurate do you need to be?

- What kind of concrete is it that needs to be broken?

The primary types of concrete hammers are: rotary hammer, demolition hammer, combination hammer, handheld breaker hammer/jack hammer and industrial hydraulic breaker. Each one has its own specialties, so you’ll have to determine the best option for the job at hand.

Rotary hammers, demolition hammers and combination hammers are all smaller, handheld tools that can be used on vertical and horizontal concrete. Note that hammer drills are different than these hammers that are made to break concrete. Hammer drills do not have a chiseling function and can be used to drill into a variety of materials.

Rotary hammers use an electro-pneumatic hammer piston to generate high impact energy, which allows it to drill or demolish concrete. For increased demolition or bigger holes through tougher concrete, combination hammers use larger, harder-hitting electro-pneumatics to generate impact. Demolition hammers can break, chip and chisel concrete, but they can’t drill because there is no rotation of the bit.

Handheld breaker hammers/jack hammers are used for breaking up horizontal slabs of concrete and other demolition tasks.

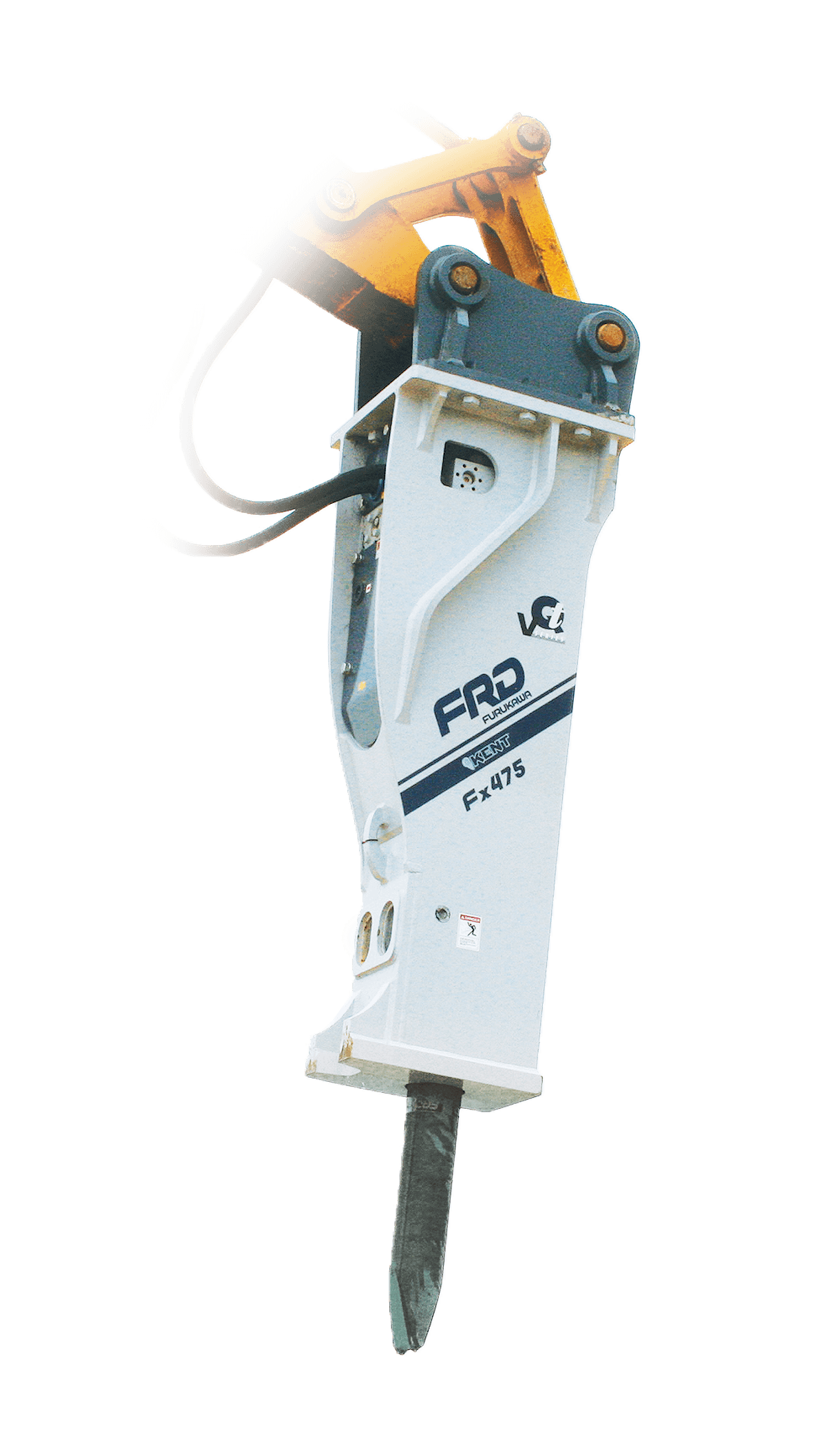

Hydraulic Breakers for Larger Jobs

For bigger jobs, hydraulic breakers are attachments that go on skid steers, compact utility loaders, backhoes, mini excavators, and excavators. When operated properly and correctly sized for the job, breakers efficiently and effectively break up concrete and shatter rock.

Hydraulic breakers are suitable for a number of applications. Beyond proper operation and appropriate sizing for the job, it’s important to choose the correct working steel for the application:

- Chisel—best used in rock and concrete

- Moil—works well in material that is loose and/or concrete that is heavily reinforced

- Blunt Tool—used in breaking up oversized boulders during secondary breaking

- Asphalt—to break up and cut through asphalt

- Tamping plate—used to compact or tamp down loose material

To learn more about hydraulic breakers and their many uses for breaking up concrete and shattering rock, call FRD USA at 800.527.2282.

Recent Posts

Beyond Breakers: A Variety of Attachments Expand What Carriers Can Do

What’s the Difference between Small, Medium and Large Breakers?

To learn more about FRD USA hydraulic breakers and how their mono-block body design can improve productivity and decrease costs, call FRD USA at 800.527.2282

Furukawa Rock Drill USA is a leading manufacturer of blast hole drills, hydraulic breakers and various other attachments for skid steer, mini excavators, backhoes and excavators. FRD USA Attachment Division (formerly marketed as Kent Demolition Tool) is a leading brand throughout North and Central America, and FRD USA Rock Drill Division offers a complete line of advanced drills and accessories for construction and quarry sites.