Saying Goodbye to Thru-Bolts: Mono-Block Body Eliminates Point of Potential Failure

Breakers with no thru-bolts reduce overall maintenance costs and expensive downtime

Demolition is a demanding job that needs breakers that can perform under pressure and are built to last. They have to withstand the stress of continuous impacts over time that will eventually result in wear and rebuilds.

In addition to routine maintenance and proper operation, the way the breaker is constructed can lower breaker life cycle costs and lengthen its longevity. Typically, hydraulic breakers have followed the industry standard of being designed with three primary components that are all tied together with thru-bolts. These three components are:

- Back Head (nitrogen chamber)

- Cylinder

- Front Head

The back head is a chamber filled with nitrogen under low pressure that functions similar to a damper for the piston stroke returning. The back head also helps improve impact as the piston moves down. The cylinder assembly mainly includes a cylinder, piston and control valve – and is the primary component of a hydraulic breaker. The piston and valve are the sole moving parts of the breaker, and it’s the piston that moves to strike the working steel. The point where the working steel connects to the piston is the front head. Pins retain the working steel.

Eliminating Thru-Bolts

Breaking away from the industry standard use of thru-bolts, a mono-block design combines the front head and cylinder into one piece. By integrating these typically separate components into a single piece of steel, thru-bolts are eliminated because they are not needed to affix the front head and cylinder to each other. They become one cohesive internal body of the breaker.

Thru-bolts are maintenance items that need to be checked periodically. Eliminating them also eliminates that part of the maintenance schedule, as well as a point of potential failure. That means overall maintenance costs, expensive downtime and life cycle costs can be reduced.

A Range of Breakers without Thru-Bolts

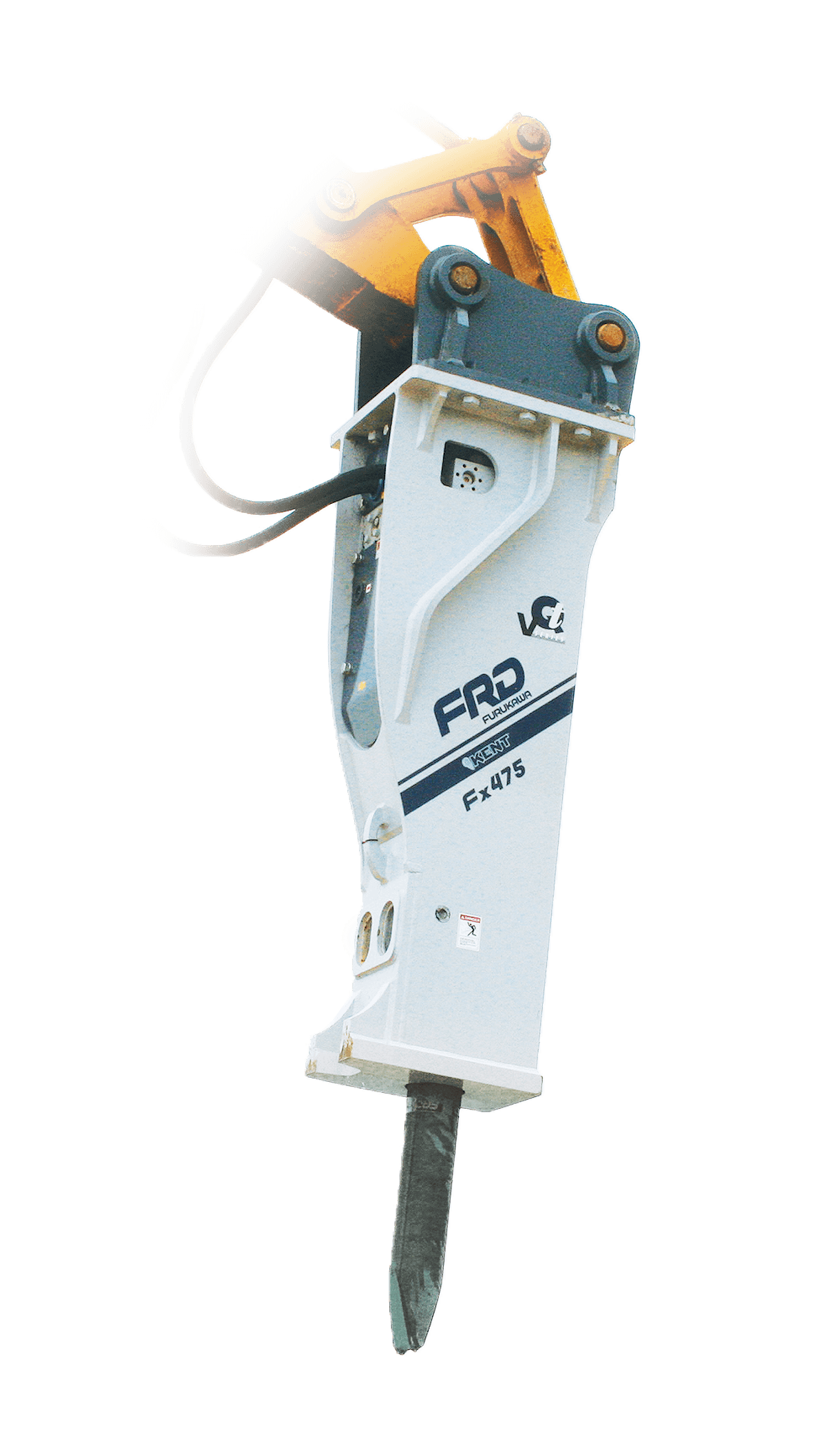

The majority of FRD USA hydraulic breakers feature the mono-block design, which means no thru-bolts. These range from small hydraulic breakers to medium-sized breakers up to large breakers.

“Thru-bolts are typically the largest parts expense in a breaker. The risk with them is that they can bend, get stripped or even break. A broken thru-bolt is bad news,” said Ted Crane, national sales manager for the FRD USA Breaker Attachment division. “We eliminated thru-bolts from almost all of our breakers, which means less maintenance and fewer problems, saving time and money.”

Learn more about FRD USA hydraulic breakers and attachments that avoid the use of thru-bolts with a mono-block design.