HydraPak – HP135 II AND HP 210 II PLATE COMPACTORS – HIGHER FREQUENCY AND HIGHER IMPACT POWER

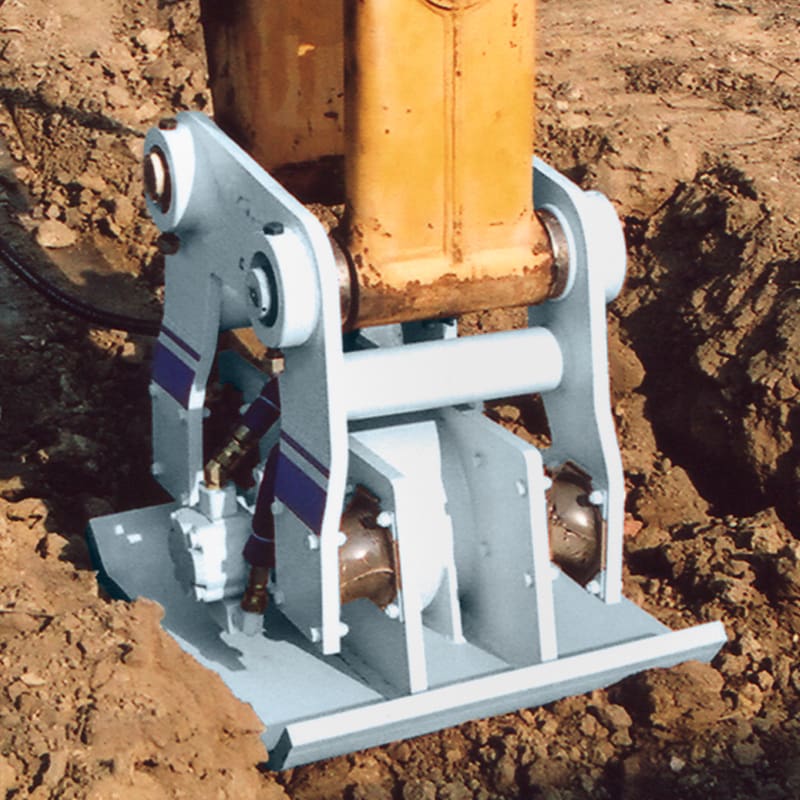

Compactor/drivers combine high frequency vibration with high impact power to make quick work of any compaction or driving task.

Designed for use on medium and large excavators, these compactors are designed to work anywhere a boom can reach in trenches, around foundations, on slopes or seawalls. HydraPaks can safely compact trenches, often eliminating the extra cost involved with a man and walk-behind unit and the added expense of trench boxes or shoring. The HydraPaks are also ideal for driving steel sheeting used for retaining walls.

Higher Impact Power

Rubber Shock-Absorbers

Reliable Performance

Hardened Steel Components

Furukawa compactor/drivers feature special rubber shock absorbers which protect the boom by isolating it from the HydraPak vibrations and a cross-over check valve protects the motor.

HP135 II delivers 13,500 lbs. of impulse force and the HP210 II delivers 21,00 lbs. of impulse force at 2,000 cycles per minute assuring maximum lift capacity. All units are built for rugged, reliable performance with hardened steel components to resist the effects of stress, vibration, fatigue and impact forces.

Improved Performance

Furukawa compactor/drivers feature special rubber shock absorbers which protect the boom by isolating it from the HydraPak vibrations and a cross-over check valve protects the motor.

HP135 II delivers 13,500 lbs. of impulse force and the HP210 II delivers 21,00 lbs. of impulse force at 2,000 cycles per minute assuring maximum lift capacity. All units are built for rugged, reliable performance with hardened steel components to resist the effects of stress, vibration, fatigue and impact forces.

Features & Benefits

- Eliminates costly trench boxes and shoring.

- Drives sheeting for retaining walls.

- Rubber shocks absorb vibration protecting the carriers boom.

- Available with O.E.M. bolt-on top cap.

- Models 135 and 210 FB II are available with our unique floating boss design that allows O.E.M. pin spacing, eliminating costly manufacturers brackets.

- Eliminates costly trench boxes and shoring.

- Drives sheeting for retaining walls.

- Rubber shocks absorb vibration protecting the carriers boom.

- Available with O.E.M. bolt-on top cap.

- Models 135 and 210 FB II are available with our unique floating boss design that allows O.E.M. pin spacing, eliminating costly manufacturers brackets.

Specifications

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 13,500 lbs (6,124 kg) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 30 GPM (114 LPM) |

| Approximate weight in lbs. (kg) | 1,335 lbs (606 kgs) |

| Approximate height in inches (mm) | 34″ (864 mm) |

| Width in inches (mm) | 28″ (711 mm) |

| Pin spacing in inches (mm) | 15.75″ (400 mm) |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 28 x 40″ (711 x 1,016 mm) |

| Compaction area sq. ft. (sq. m) | 7.8 sq. ft. (.72 sq. m) |

| Pressure line in inches (mm) | 0.75″ (19 mm) |

| Return line in inches (mm) | 1″ (25 mm) |

| Carrier options | Mini Excavator, Backhoe, Wheeled Excavator, Excavator |

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 13,500 lbs (6,124 kgs) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 30 GPM (114 LPM) |

| Approximate weight in lbs. (kg) | 1,470 lbs (667 kgs) |

| Approximate height in inches (mm) | 34″ (864 mm) |

| Width in inches (mm) | 28″ (711 mm) |

| Pin spacing in inches (mm) | O.E.M. |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 28 x 40″ (711 x 1,016 mm) |

| Compaction area sq. ft. (sq. m) | 7.8 sq. ft. (.72 sq. m) |

| Pressure line in inches (mm) | 0.75″ (19 mm) |

| Return line in inches (mm) | 1″ (25 mm) |

| Carrier options | Mini Excavator, Backhoe, Wheeled Excavator, Excavator |

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 13,500 lbs (6,124 kgs) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 30 GPM (114 LPM) |

| Approximate weight in lbs. (kg) | 1,770 lbs (803 kgs) |

| Approximate height in inches (mm) | 27″ (686 mm) |

| Width in inches (mm) | 28″ (711 mm) |

| Pin spacing in inches (mm) | O.E.M. |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 28 x 40″ (711 x 1,016 mm) |

| Compaction area sq. ft. (sq. m) | 7.8 sq. ft. (.72 sq. m) |

| Pressure line in inches (mm) | 0.75″ (19 mm) |

| Return line in inches (mm) | 1″ (25 mm) |

| Carrier options | Mini Excavator, Backhoe, Wheeled Excavator, Excavator |

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 21,000 lbs (9,525 kgs) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 48 GPM (182 LPM) |

| Approximate weight in lbs. (kg) | 2,150 lbs (975 kgs) |

| Approximate height in inches (mm) | 39.5″ (1,003 mm) |

| Width in inches (mm) | 34″ (864 mm) |

| Pin spacing in inches (mm) | 18.7″ (475 mm) |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 34 x 46″ (864 x 1,168 mm) |

| Compaction area sq. ft. (sq. m) | 10.8 sq. ft. (1.0 sq. m) |

| Pressure line in inches (mm) | 1″ (25 mm) |

| Return line in inches (mm) | 1.25″ (32 mm) |

| Carrier options | Wheeled Excavator, Excavator |

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 21,000 lbs (9,525 kgs) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 48 GPM (182 LPM) |

| Approximate weight in lbs. (kg) | 2,235 lbs (1,014 kgs) |

| Approximate height in inches (mm) | 39.5″ (1,003 mm) |

| Width in inches (mm) | 34″ (864 mm) |

| Pin spacing in inches (mm) | O.E.M. |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 34 x 46″ (864 x 1,168 mm) |

| Compaction area sq. ft. (sq. m) | 10.8 sq. ft. (1.0 sq. m) |

| Pressure line in inches (mm) | 1″ (25 mm) |

| Return line in inches (mm) | 1.25″ (32 mm) |

| Carrier options | Wheeled Excavator, Excavator |

| Title | Unit |

|---|---|

| Impulse force lbs. (kg) | 21,000 lbs (9,525 kgs) |

| Cycles per minute | 2,000 |

| Operating pressure psi (Bar) | 2,000 psi (138 Bar) |

| Hydraulic flow req’d GPM (LPM) | 48 GPM (182 LPM) |

| Approximate weight in lbs. (kg) | 2,730 lbs (1,238 kg) |

| Approximate height in inches (mm) | 32″ (813 mm) |

| Width in inches (mm) | 34″ (864 mm) |

| Pin spacing in inches (mm) | O.E.M. |

| Mounting pin diameter | As required |

| Base plate dimensions in inches (mm) | 34 x 46″ (864 x 1,168 mm) |

| Compaction area sq. ft. (sq. m) | 10.8 sq. ft. (1.0 sq. m) |

| Pressure line in inches (mm) | 1″ (25 mm) |

| Return line in inches (mm) | 1.25″ (32 mm) |

| Carrier options | Wheeled Excavator, Excavator |

Notes

Weight does not include pins and bushings for all models or bolt-on top cap for Ft models.