What Problems Can Happen When Drilling into the Earth?

Drilling holes into the earth for mining, rock excavation and more can present many challenges, regardless of the purpose of the drilling (blastholes, construction, exploration, oil and gas, foundation, etc.). Even when using high-performance, reliable rock drilling equipment, problems can still arise. Some of these include:

- Drill pipe sticking — there are several factors that can cause this, with the primary one being a shift in the rock formation and debris falling back in the hole, which causes the rotation to not work properly.

- Lost circulation — a malfunction in the rotation motor leads to lost rotation.

- Hole deviation — when drilling, the goal is to have a straight hole from top to bottom. Hole deviation means the drill string is drifting. For example, the bottom of the hole may be a number of feet in either direction from the top.

- Drill string failures — occurs when a drill steel is bent, or couplers break or bind, causing failure in the ability to remove or add steel to the hole.

- Mud contamination — can happen when a mud seam in the earth is hit, which occasionally plugs air flow.

- Formation damage — makes for more difficult drilling because there might be a rock that has been disturbed in the past or there are many different types of rock and seams. This makes for tougher drilling conditions.

- Bore hole instability — this is essentially a larger hole that will not maintain its shape, such as big voids in the rock, etc. This is common in a shale type of aggregate.

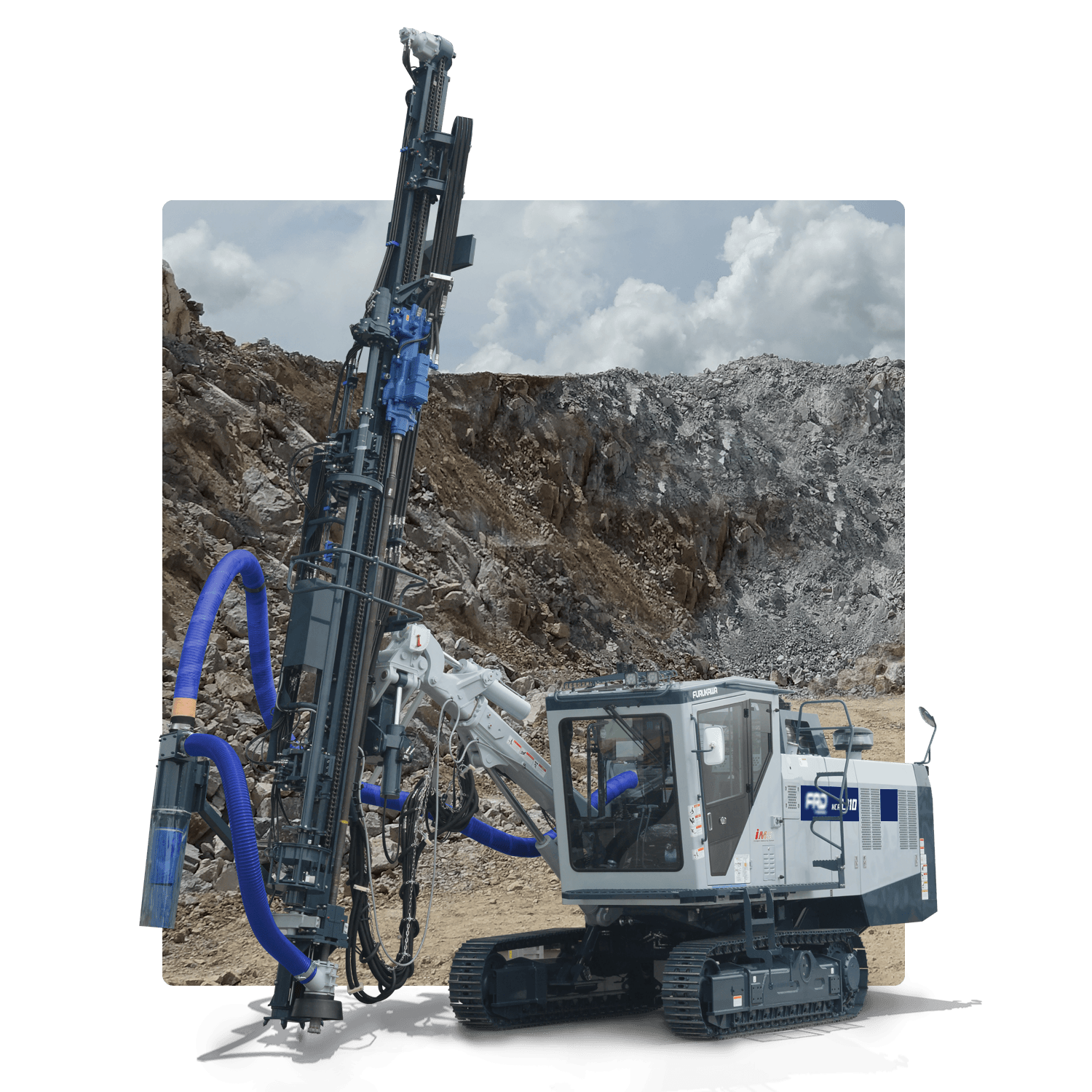

If you encounter any of these problems when drilling and need assistance, contact your authorized FRD USA dealer or contact FRD USA Rock Drill Division directly at 800.358.4476.

Recent Posts

Scott Zimmer2023-11-15T15:36:58+00:00