HCR L110-E5 ROCK DRILL – TWO DRIFTER OPTIONS FOR INCREASED VERSATILITY

By automatically controlling the impact force, feed force, rotation force and dual damper pressure, the HCR L110 continuously adapts to the changing rock conditions, increasing drilling performance and the life of drill tools while decreasing fuel consumption.

By automatically controlling the impact force, feed force, rotation force and dual damper pressure, the HCR L110 continuously adapts to the changing rock conditions, increasing drilling performance and the life of drill tools while decreasing fuel consumption.

Low-emission C9 3B engine offers low fuel consumption and meets US exhaust emissions regulations. Whether you choose the HD828 drifter or step-up to the HD836, you will benefit from dependable performance and easy operation.

With FRD’s TFSS (total fuel savings system), the operator selects the optimum engine speed for the application, allowing all fuel savings functions to be automatically managed during drilling operation.

HCR L110-E5 Features & Benefits

- Advanced rotary rod changer allows easy drill rod changes. Operators can add and remove rods using a single lever.

- HCR L110-E5 features 12′ or 14′ rods with extendable boom for increased drill pattern.

- Heavy-duty undercarriage – featuring a pentagonal section design to reduce dirt build-up and track wear – ensures strength and durability.

- High-output compressor increases flushing air, provides faster drilling and decreases bit wear.

- Reliable dust control system with increased suction capacity provides effective pre-cleaning to reduce the escape of rock dust. An optional dust suppression system is available for difficult drilling conditions.

- Choose from an HD828 or HD836 drifter to meet your specific application needs.

- Advanced rotary rod changer allows easy drill rod changes. Operators can add and remove rods using a single lever.

- HCR L110-E5 features 12′ or 14′ rods with extendable boom for increased drill pattern.

- Heavy-duty undercarriage – featuring a pentagonal section design to reduce dirt build-up and track wear – ensures strength and durability.

- High-output compressor increases flushing air, provides faster drilling and decreases bit wear.

- Reliable dust control system with increased suction capacity provides effective pre-cleaning to reduce the escape of rock dust. An optional dust suppression system is available for difficult drilling conditions.

- Choose from an HD828 or HD836 drifter to meet your specific application needs.

Specifications

| Title | Unit |

|---|---|

| Overall weight in lbs. (kg) | 45,415 lbs (20,600 kgs) |

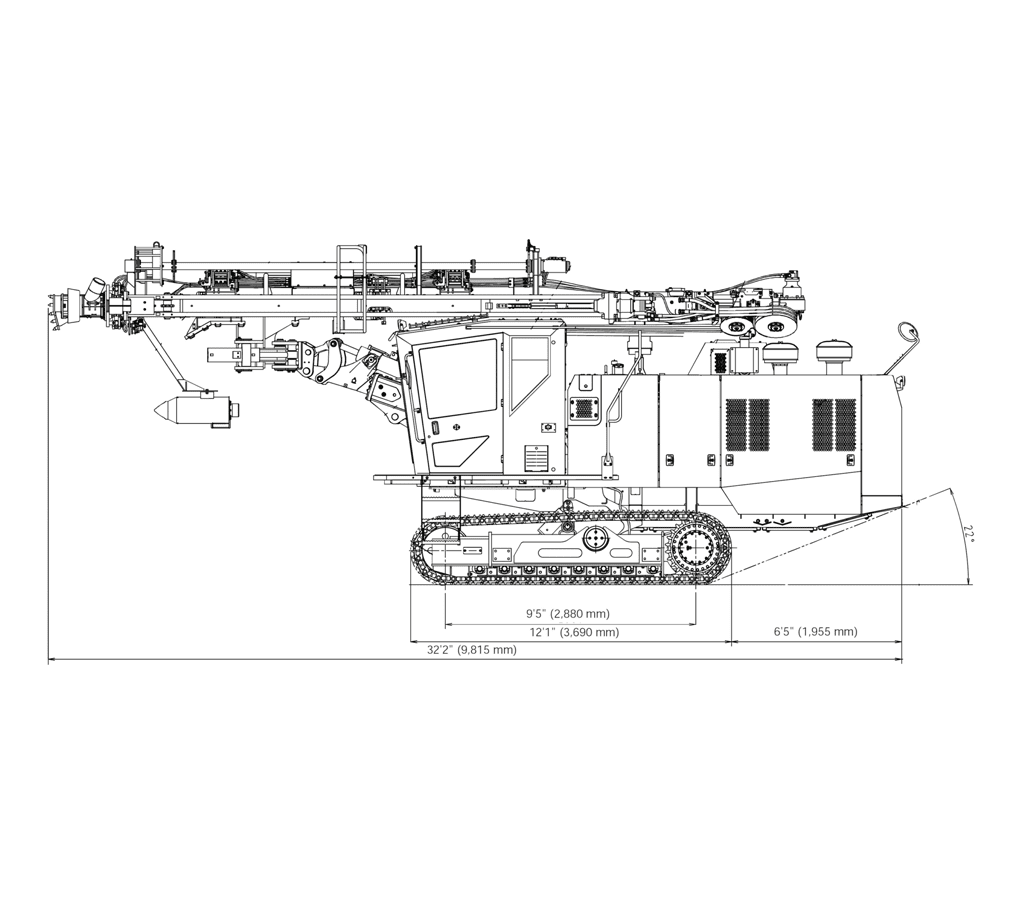

| Overall length in inches (mm) | 32′10″ (10,015 mm) |

| Shipping length in inches (mm) | 36′7″ (11,160 mm) |

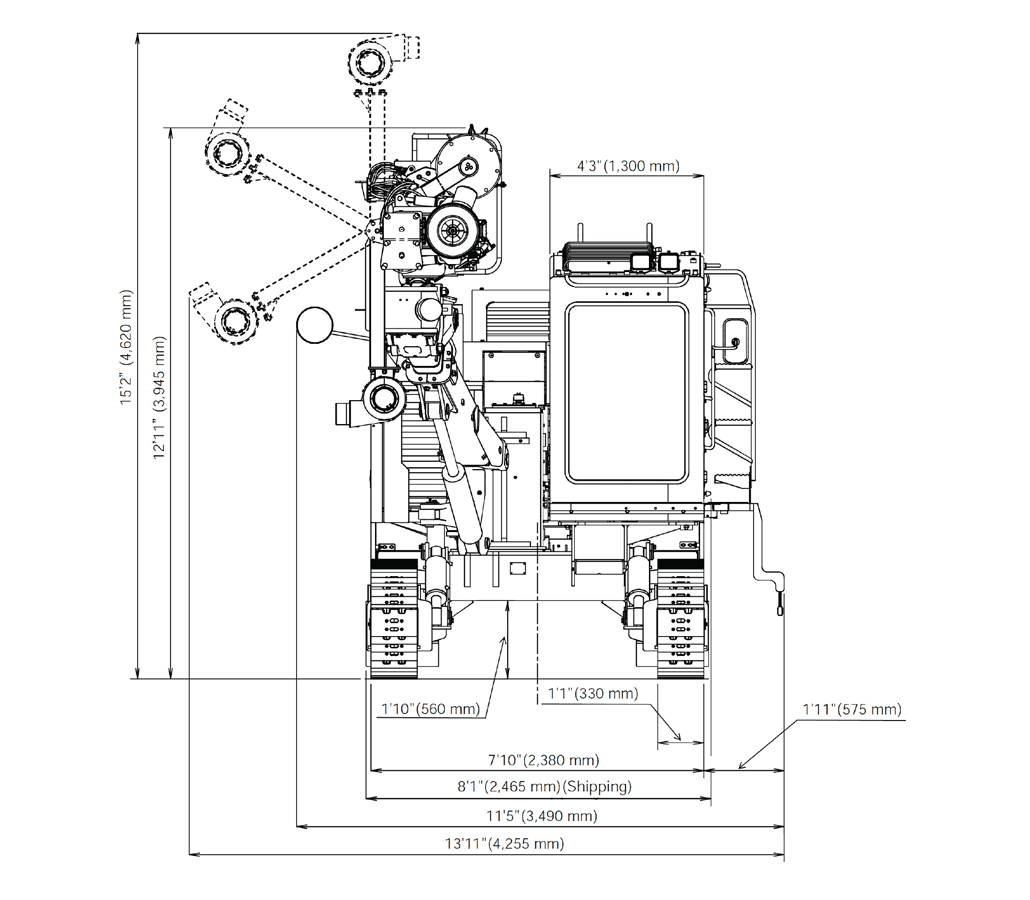

| Overall width in inches (mm) | 11′5″ (3,490 mm) |

| Shipping width in inches (mm) | 8′1″ (2,465 mm) |

| Overall height in inches (mm) | 15′2″ (4,620 mm) |

| Shipping height in inches (mm) | 11′7″ (3,520 mm) |

| Title | Unit |

|---|---|

| Model | HD828 |

| Weight in lbs. (kg) | 597 lbs (271 kg) |

| Length in inches (mm) | 3′9″ (1,148 mm) |

| Width in inches (mm) | 1′3″ (387 mm) |

| Height in inches (mm) | 1′1″ (328 mm) |

| Number of blows BPM | 2,700 – 3,300 BPM |

| Rotating speed | 0 – 190 rpm (0-190 min-1) |

| Title | Unit |

|---|---|

| Track length in inches (mm) | 12′1″ (3,690 mm) |

| Track length on ground in inches (mm) | 9′5″ (2,880 mm) |

| Track width in inches (mm) | 1′1″ (330 mm) |

| Ground contact pressure | 14.8 psi (101.8 kPa) |

| Ground clearance in inches (mm) | 1′10” (560 mm) |

| Frame oscillation angle | ±7.5° |

| Tramming speed | 0 – 2.0 mph (0 – 3.3 km/h) |

| Gradeability | 57.4% (30°) |

| Maximum traction force | 28,551 lb-force (127 kN) |

| Title | Unit |

|---|---|

| Make & model | CAT® / C9.3B (Tier4Final, Stage V) |

| Type | Diesel, Water-Cooled, 6 Cylinders |

| Piston displacement | 567.5 cu in (9.3 L) |

| Power output | 375 hp/2,200 rpm (280 kW/2,200 min-1) |

| Fuel capacity | 158.5 gal (600 L) |

| DEF capacity | 11.8 gal (44.7 L) |

| Title | Unit |

|---|---|

| Variable displacement pump | PV Pump x2 |

| Fixed displacement pump | Gear Pump X3 |

| Hydraulic oil reservoir capacity | 63.4 gal (240 L) |

| Title | Unit |

|---|---|

| Model | JE326-134 |

| Type | Extension Boom |

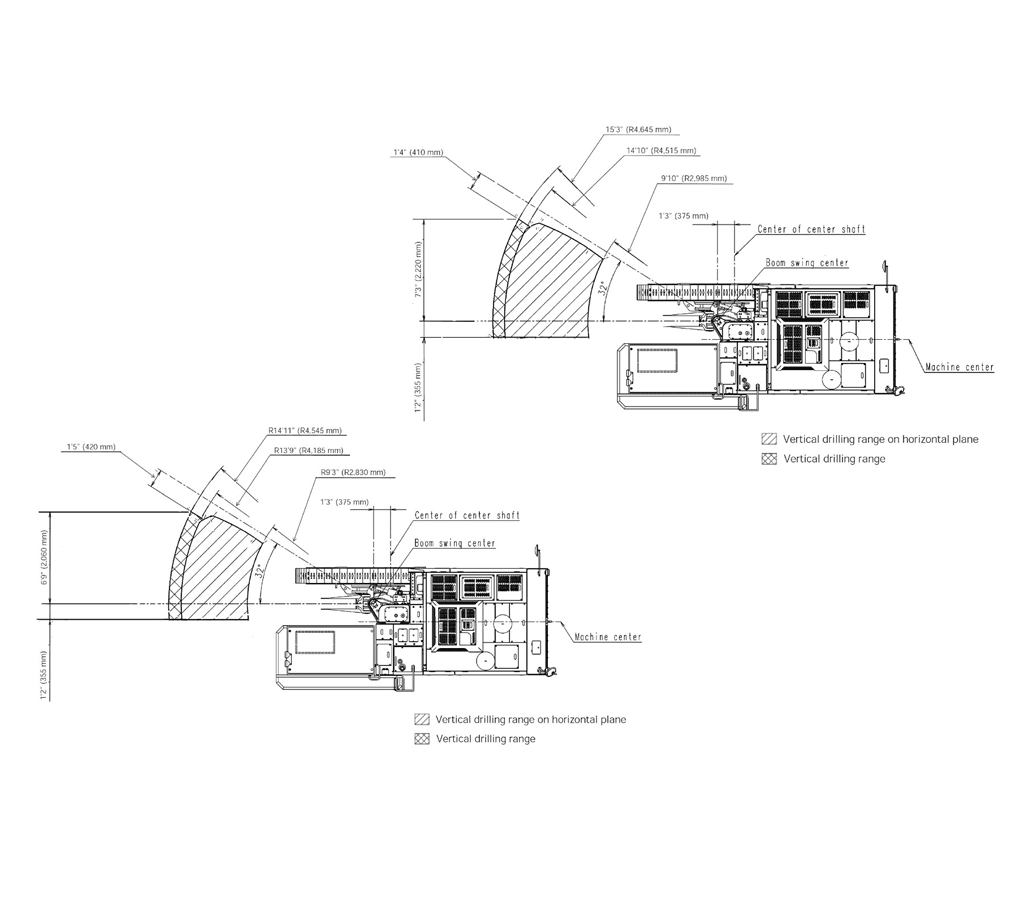

| Boom lifting angle: up/down | 41° / 20° |

| Boom swing Aangle: right/left | 32° / 0° |

| Boom slide length in inches (mm) | 2′11” (900 mm) |

| Title | Unit |

|---|---|

| Model | GH832-33 |

| Length in inches (mm) | 28′7″ (8,700 mm) |

| Feed length (for 14′) in inches (mm) | 17′2″ (5,225 mm) |

| Feed length (for 12′) in inches (mm) | 15′1″ (4,595 mm) |

| Feed type | Hydraulic Motor Driven Chain |

| Guide slide length in inches (mm) | 4′11” (1,500 mm) |

| Guide swing angle: right/left | 25° / 90° |

| Guide tilt angle | 170° |

| Maximum pulling force | 7,644 lb-force (34 kN) |

| Title | Unit |

|---|---|

| Make & model | AIRMAN / PDSF290-S16 |

| Type | 1-Stage Screw Compressor |

| Discharge airflow CFM | 477 CFM (13.5 m3/min) |

| Discharge pressure | 149 psi (1.03 MPa) |

| Title | Unit |

|---|---|

| Model | A885-44 |

| Suction capacity CFM | 1,413 CFM (40 m³/min) |

| Number of filter elements | 6 |

| Dust removal system | Automatic Pulse Air Jet |

| Suction cap | Slide Type |

| Title | Unit |

|---|---|

| Model | GR803-31 |

| Number of rod storage | 7 (For T51) pcs |

| Rod diameter in inches (mm) | 2″ (51 mm) |

| Number of control levers | 1 pcs |

| Title | Unit |

|---|---|

| Bit range in inches (mm) | 4.0″ - 5.0″ (102 - 127 mm) |

| Rod type | T51 |

| Rod length in inches (mm) | 12′/14′ (3,660 mm/4,270 mm) |

| Starter rod length in inches (mm) | 14′ (4,270 mm) |

| Title | Unit |

|---|---|

| Battery | 12V; 160Ah/5h x2 |

| Light | 24V; 70W x4 |

| Voltage | DC 24V |

| Title | Unit |

|---|---|

| Working temperature | 5° to 113° F / −15° to +45° C |

| Maximum altitude | 8,202′ (2,500 m) |

Options

Water / Dust Suppression System – 35 gal

Water / Dust Suppression System – 70 gal

2D Angle Indicator

3D Angle Indicator

All-In-One 3D Angle Indicator

Rear & Side View Camera With An Optional Separate Monitor

Rear Bumper

Cold Weather Kit (Esper, Webasto)

Heating Pad

Hand Rail

Central Greaser

Dependable Blasthole Drills Start at Step One

Blasthole rigs and drills don’t need much explanation. They’re used for drilling a hole into the surface of the rock, packing the hole with explosives and then detonating those explosives in the blasthole to break up rock and hard minerals to make it easier to remove.

If you are interested in learning more, download our guide on choosing the right rock drill for your job.