HCR1100-ER ROCK DRILL – BETTER PENETRATION WITH INCREASED IMPACT

The HCR1100-ER drill incorporates innovative features for higher output and is capable of drilling at larger diameters.

Utilizing a Cummins® Tier-IV EPA compliant engine, the HCR1100-ER combines higher performance with fuel efficiency.

The Furukawa HD822 drifter (patent applied for) is designed to minimize drill noise and vibration, while increasing performance. With 26.7% more impact and 13% more airflow than its predecessor, this drill has the ability to perform in harder rock at a larger diameter.

HCR1100-ER Features & Benefits

- The improved electro-hydraulic controls allow easier operation.

- With FRD’s TFSS (total fuel savings system), the operator selects the optimum engine speed for the application, allowing all fuel savings functions to be automatically managed during drilling operation.

- The monitoring system incorporates gauges next to the drilling station, allowing the operator a quick visual of engine temperature, hydraulic oil temperature and fluid levels.

- Automatic rod changer eliminates the need for operators to manually install drill steel, resulting in increased production and enhanced operator safety.

- Upgraded compressor increases free air delivery by nearly 28% to accommodate larger diameter drilling.

- Winch-ready frame adds application versatility.

- Optional wireless remote allows tramming and drilling from a secondary location.

- The improved electro-hydraulic controls allow easier operation.

- With FRD’s TFSS (total fuel savings system), the operator selects the optimum engine speed for the application, allowing all fuel savings functions to be automatically managed during drilling operation.

- The monitoring system incorporates gauges next to the drilling station, allowing the operator a quick visual of engine temperature, hydraulic oil temperature and fluid levels.

- Automatic rod changer eliminates the need for operators to manually install drill steel, resulting in increased production and enhanced operator safety.

- Upgraded compressor increases free air delivery by nearly 28% to accommodate larger diameter drilling.

- Winch-ready frame adds application versatility.

- Optional wireless remote allows tramming and drilling from a secondary location.

Specifications

| Title | Unit |

|---|---|

| Operating weight with fuel & oil in lbs. (kg) | 27,500 lbs (12,460 kgs) |

| Travel speed | 0 - 2 mph (0 - 3.2 km/h) |

| Maximum traction force | 19,700 lb-force (88 kN) |

| Maximum grade of hill climb | 57.7% (30°) |

| Oscillating angle | ±7.6° |

| Ground clearance in inches (mm) | 23″ (585 mm) |

| Ground contact pressure *3 | 11.2 psi (77.3 kPa) |

| Title | Unit |

|---|---|

| Model | HD 822 |

| Operating weight in lbs. (kg) | 533 lbs (242 kgs) |

| Power | 29.5 hp (22 kW) |

| Overall length in inches (mm) | 44.5″ (1,130 mm) |

| Overall width in inches (mm) | 14.7″ (373 mm) |

| Overall depth in inches (mm) | 12.9″ (328 mm) |

| Number of blows BPM | 2,700 - 3,300 BPM |

| Number of revolutions | 190 rpm (190 min-1) |

| Title | Unit |

|---|---|

| Make & model | Cummins® QSB6.7 |

| Type | Water Cooled, 6-Cylinder Diesel Engine |

| Rated output | 226 hp/2,200 rpm / 168 kW/2,200 min-1 |

| Emission control | Tier-IV Final |

| Fuel capacity | 84 gal (320 L) |

| DEF capacity | 5 gal (19 L) |

| Title | Unit |

|---|---|

| Variable displacement pump | Axial Piston Pump X2 |

| Fixed displacement pump | Gear Pump X3 |

| Drive motor | Hydraulic Motor with Reduction Gear |

| Title | Unit |

|---|---|

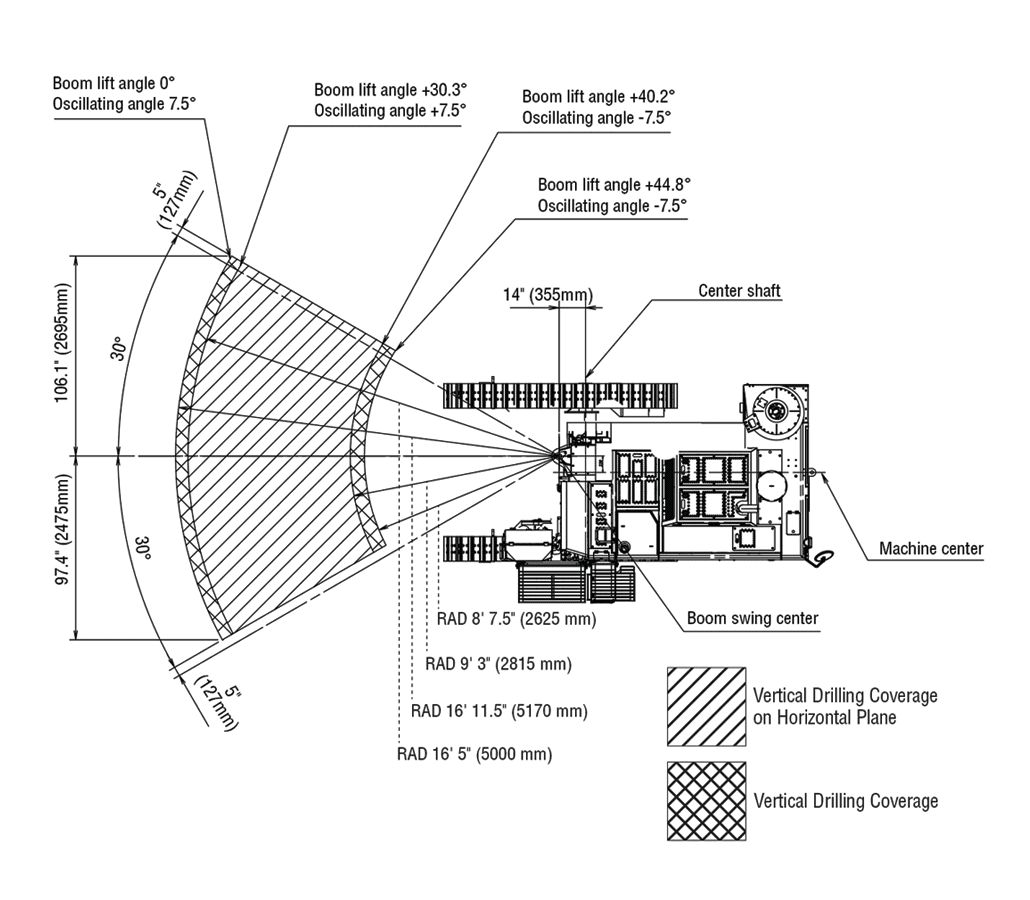

| Model | JE326 |

| Type | Extension Boom |

| Boom lifting angle: up/down | 45°/15° |

| Boom swing angle: right/left | 30°/30° |

| Boom slide length in inches (mm) | 3′11″ (1,200 mm) |

| Title | Unit |

|---|---|

| Model | GH831 |

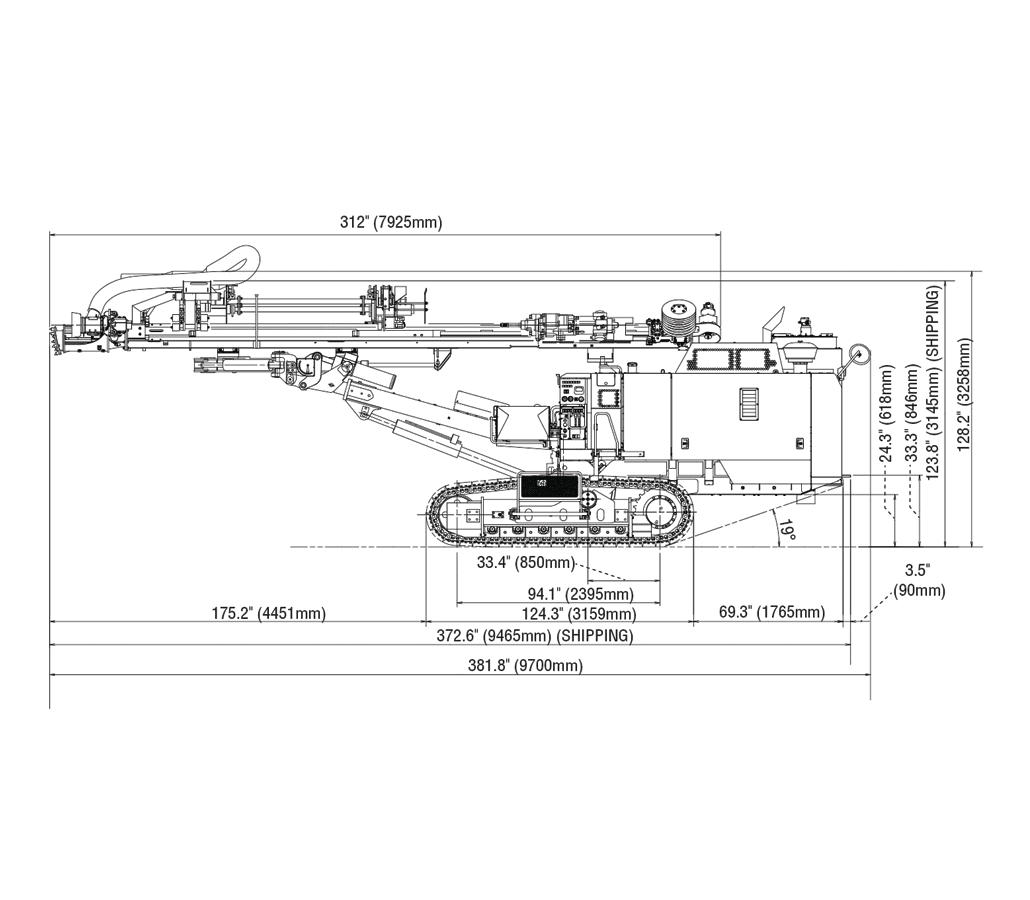

| Overall length in inches (mm) | 26′0″ (7,925 mm) |

| Feed length in inches (mm) | 15′8″ (4,781 mm) |

| Guide slide length in inches (mm) | 3′11″ (1,200 mm) |

| Guide swing angle: right/left | 30°/90° |

| Guide tilt angle | 180° |

| Maximum pulling force | 7,060 lb-force (31.4 kN) |

| Feed system | Motor Chain |

| Title | Unit |

|---|---|

| Make & model | AIRMAN PDS265-S37C |

| Type | Screw 1-Stage |

| Discharge airflow | 275 CFM (7.8 m3/min) |

| Discharge pressure | 149 psi (1.03 Mpa) |

| Title | Unit |

|---|---|

| Model | A844 |

| Airflow | 918 CFM (26 m3/min) |

| Number of elements | 5 |

| Dust removal system | Automatic Pulse Air Jet |

| Suction cap | Slide Type |

| Title | Unit |

|---|---|

| Number of rods | 5 |

| Rod length T38 – T45 in inches (mm) | 10′/12′ (3.05 mm/3.66 mm) |

| Title | Unit |

|---|---|

| Battery | 12V; 108Ah/5hr |

| Voltage | DC 24V |

| Title | Unit |

|---|---|

| Fuel tank | 84 gal (320 L) |

| Hydraulic tank | 45 gal (170 L) |

| DEF tank *4 | 5 gal (19 L) |

| Title | Unit |

|---|---|

| Bit diameter in inches (mm) | 2.5″ - 4″ (64 mm - 102 mm) |

| Rod size | T38 - T45 |

| Rod length in inches (mm) | 10′ or 12′ (3,050 mm or 3,660 mm) |

| First rod length maximum in inches (mm) | 13′ (4,000 mm) |

| Title | Unit |

|---|---|

| Operating temperature | 5° to 113° F / −15° to +45° C |

Options

Water / Dust Suppression System – 35 gal

Water / Dust Suppression System – 70 gal

Remote Control

2D Angle Indicator

Rear Bumper

Cold Weather Kit (Esper, Webasto)

Heating Pad

Dependable Blasthole Drills Start at Step One

Blasthole rigs and drills don’t need much explanation. They’re used for drilling a hole into the surface of the rock, packing the hole with explosives and then detonating those explosives in the blasthole to break up rock and hard minerals to make it easier to remove.

If you are interested in learning more, download our guide on choosing the right rock drill for your job.