Drifters

Advanced Systems Designed to Drill Faster and Straighter

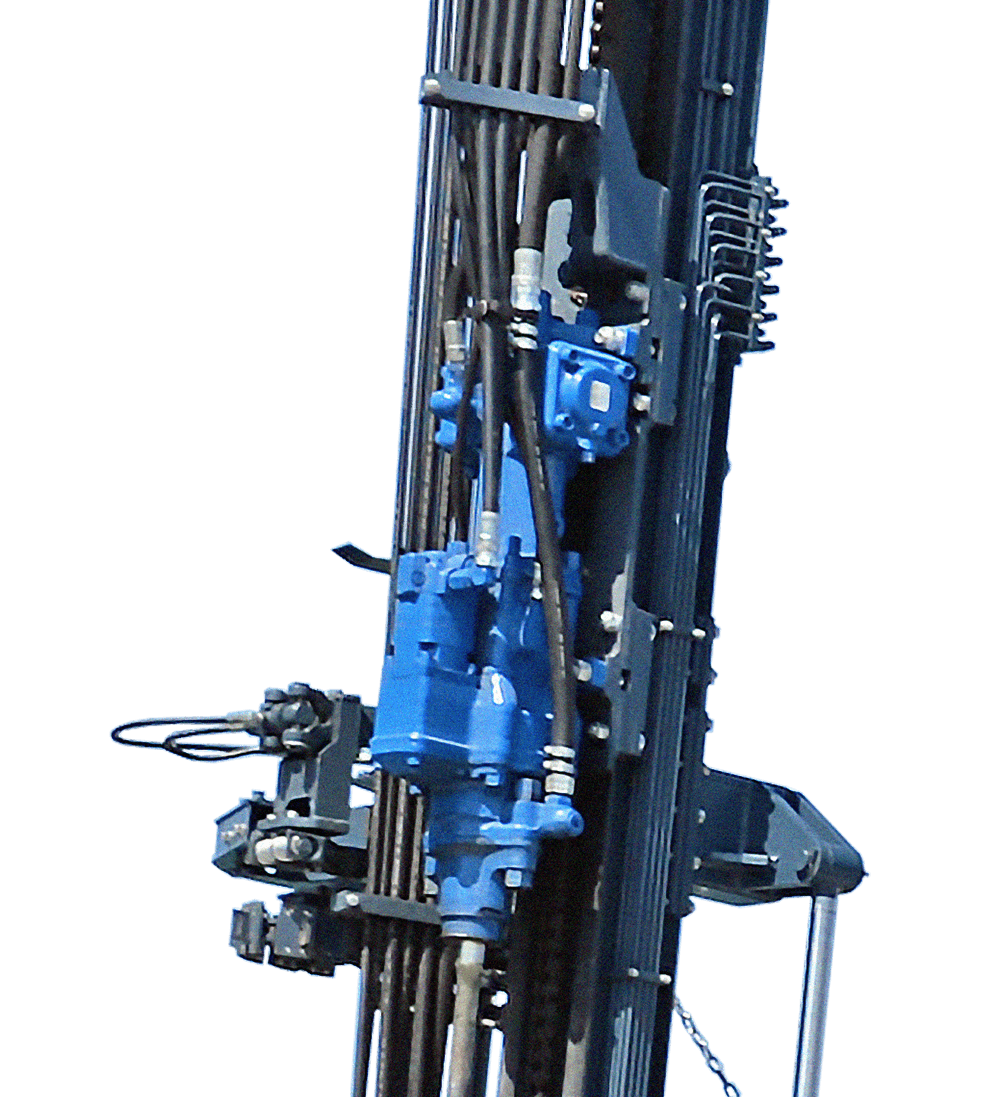

The HD 800 Series drifters (patent applied for) provide greater penetration with increased impact. With 20% more impact than its predecessor, the HD 800 Series performs in harder rock and drills larger diameters. Designed around DDS (Dual-Damper System), drilling adjusts automatically for maximum performance regardless of rock.