Tier 4 Drills Combine High Performance, Fuel Efficiency and Regulatory Compliance

Large diameter rock drilling needs large rock drills—and that means using higher horsepower engines that can maximize efficiency to deliver high-performance at a low operating cost. For more than a decade, Tier 4 engines have been the standard for off-highway diesel engines, including in blasthole drills.

Tier 4 engines have the most stringent Environmental Protection Agency (EPA) emissions standards for non-road diesel engines. Compared to older engines (Tier 3 and below), Tier 4 engines reduce two key pollutants: particulate matter (PM) and nitrogen oxides (NOx). NOx are known to contribute to the formation of ground-level ozone and PM (black soot) exposure has been shown to have adverse health effects on the respiratory system.

A History of the Tiered System

The EPA introduced its tiered system for regulating diesel engine emissions in 1996. The initial standards were phased in over several years. Since then, the criteria for the power and application of the engines required to meet those standards were broadened. In 1998, the EPA included non-road applications under the standards. In 2004, the EPA introduced stricter (Tier 4) engine standards. These were phased in starting in 2008 with Tier 4 Final requirements fully implemented in 2015. By the time final Tier 4 regulations were fully implemented, PM and NOx emissions had been reduced 99% compared to 1996 levels.

Achieving Reductions

Engine manufacturers, like Cummins and Caterpillar, have achieved these reductions through a combination of in-cylinder technologies and after–treatment systems that work together to greatly reduce PM and NOx emissions. These strategies include:

- Advanced fuel systems and turbocharging

- Exhaust gas recirculation (EGR) to reduce NOx emissions by cooling and recirculating exhaust gases

- Diesel particulate filters (DPFs) to trap and burn off soot.

- Selective catalytic reduction (SCR), which injects diesel exhaust fluid (DEF) into the exhaust to convert NOx into nitrogen and water.

FRD USA Tier 4 Drills

While emissions have been greatly reduced, today’s Tier 4 engines continue to maximize productivity and reliability across rock drills and tough environments. FRD USA offers multiple top-hammer rock drills and a down-the-hole drill with Tier 4 engines that meet strict North American exhaust emissions regulations while delivering higher performance and fuel efficiency.

HCR900-ESV Drill

Combining performance and economy, the HCR900-ESV is designed for quarries or construction sites. Simple, durable and efficient with an overall weight of 24,317 lbs., the HCR900-ESV with extendable boom incorporates a self-adjusting drill system that ensures high productivity no matter what the drilling situation.

| Engine | |

|---|---|

| Make and Model |

Cummins® QSB6.7 (Tier4 Final, Stage IV) |

| Type |

Diesel, Water-Cooled, 6 Cylinders |

| Piston displacement |

408.9 cu in (6.7 L) |

| Power output |

225.3 hp/2,200 rpm / 168 kW/2,200 min-1 |

| Fuel Capacity |

84.5 gal (320 L) |

| DEF Capacity | 5 gal (19 L) |

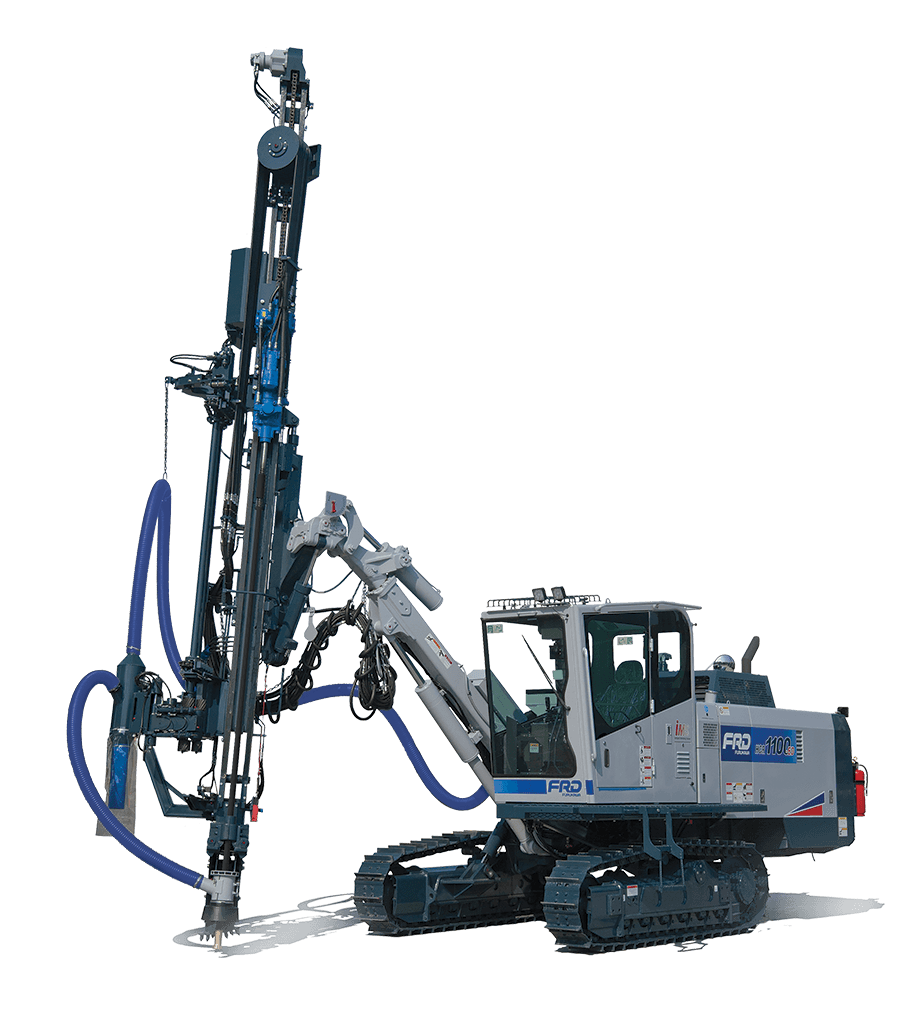

HCR1100-ER Drill

The HCR1100-ER drill incorporates innovative features for higher output, capable of drilling at larger diameters and has an overall weight of 27,500 lbs. The Furukawa HD822 drifter (patent applied for) is designed to minimize drill noise and vibration, while increasing performance. With 26.7% more impact and 13% more airflow than its predecessor, the HCR1100-ER has the ability to perform in harder rock at a larger diameter.

| Engine | |

|---|---|

| Make and Model |

Cummins® QSB6.7 |

| Type |

Water-Cooled, 6 Cylinder Diesel Engine |

| Piston displacement |

226 hp/2,200 rpm / 168 kW/2,200 min-1 |

| Power output |

Tier-IV Final |

| Fuel Capacity |

84 gal (320 L) |

| DEF Capacity | 5 gal (19 L) |

HCR1100-ED Drill

At 28,991 lbs., the HCR1100-ED with extendable boom incorporates a self-adjusting drill system that ensures high productivity no matter what the drilling situation. The Furukawa HD818 drifter (patent applied for) is designed to minimize drill noise and vibration, while increasing percussion frequency by 24% versus the HD709 drifter, its predecessor.

| Engine | |

|---|---|

| Make and Model |

Cummins® QSB6.7 |

| Type |

Water-Cooled, 6 Cylinder Diesel Engine |

| Piston displacement |

408.9 cu in 6.7 L |

| Power output |

226 hp/2,200 rpm (168 kW/2,200 min-1) |

| Fuel Capacity |

84 gal (320 L) |

| DEF Capacity | 5 gal (19 L) |

HCRL90-E5 Drill

With the on-the-fly adjustability of impact force, feed force, rotation force with the aid of a dual damper drifter, the 37,060 lb. HCRL90-E5 adapts to various rock conditions experienced at different depths to increase drilling performance and extend the life of drill tools while decreasing fuel consumption.

| Engine | |

|---|---|

| Make and Model |

Cummins® / B6.7 (Stage V, Tier4 Final) |

| Type |

Diesel, Water-Cooled, 6 Cylinders |

| Piston displacement |

408.9 cu in (6.7 L) |

| Power output |

260 hp/2,500 rpm (194 kW/2,500 min-1) |

| Fuel Capacity |

112.3 gal (425 L) |

| DEF Capacity |

15 gal (56.8 L) |

HCR L110-E5 Drill

The 45,415 lb. HCR L110-E5 has a low-emission CAT® C9 3B engine that offers low fuel consumption and meets U.S. exhaust emissions regulations. Fuel savings are further optimized with FRD’s TFSS (total fuel savings system). With it, the operator selects the optimum engine speed for the application, allowing all fuel savings functions to be automatically managed during drilling operation.

| Engine | |

|---|---|

| Make and Model |

CAT® / C9.3B (Tier 4 Final, Stage V) |

| Type |

Diesel, Water-Cooled, 6 Cylinders |

| Piston displacement |

567.5 cu in (9.3 L) |

| Power output |

375 hp/2,200 rpm (280 kW/2,200 min-1) |

| Fuel Capacity |

158.5 gal (600 L) |

| DEF Capacity |

11.8 gal (44.7 L) |

DCRL130 Down-the-Hole Drill

The DCRL130 down-the-hole (DTH) drill uses a clean engine that complies with emission regulations (EPA Tier 4 Final / EU Stage V). The “Super Economy Mode PLUS” cutting-edge fuel-saving technology allows the operator to select the engine speed during drilling operations according to rock quality, reducing fuel consumption while maintaining drilling performance.

| Engine | |

|---|---|

| Make and Model |

CAT® / C13 (Tier 4 Final, Stage V) |

| Type |

Diesel, Water-Cooled, 6 Cylinders |

| Piston displacement |

3.3 gal (12.5 L) |

| Power output |

456 hp/2,000 rpm (340 kW/2,000 min-1) |

| Fuel Capacity |

192.8 gal (730 L) |

| DEF Capacity |

18.5 gal (70 L) |