DCRL130 – PROVEN. RELIABLE. HIGH PERFORMING.

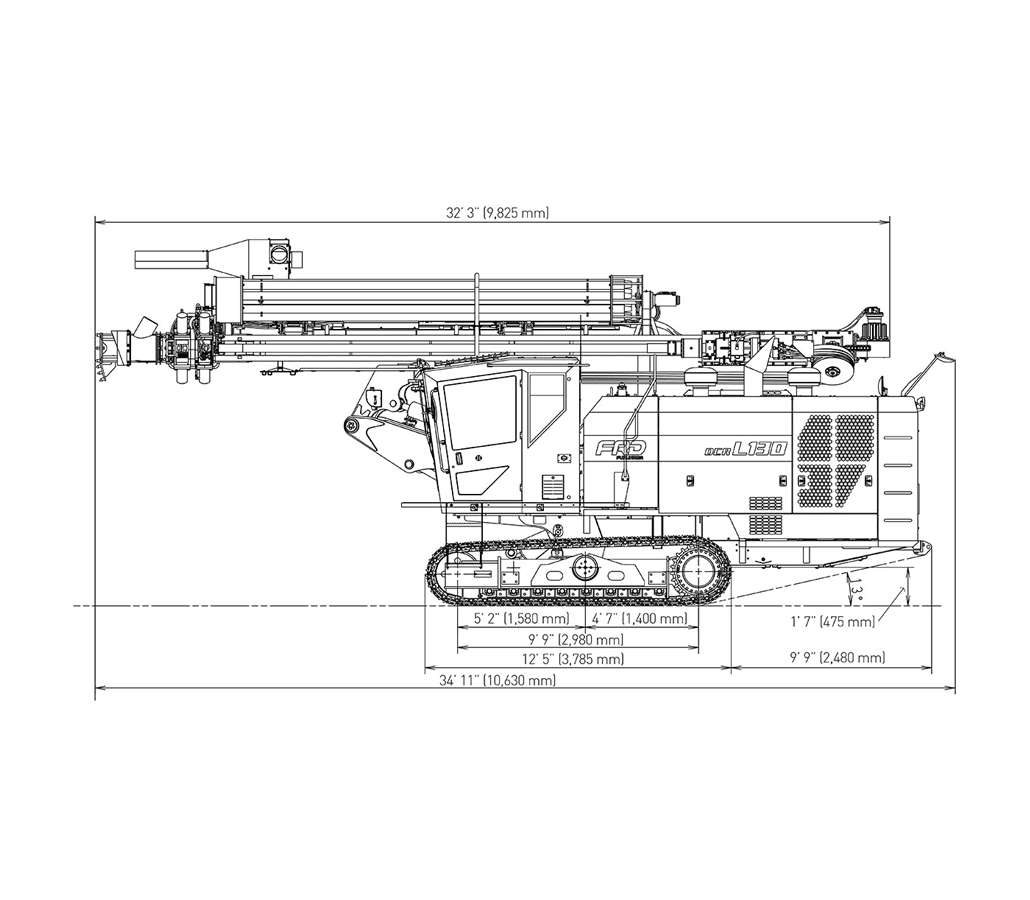

The DCRL130 – Environmentally friendly and compliant down-the-hole (DTH) rock drill with market-specific emission regulations.

These drills have been proven in soft, medium and hard rock conditions with multiple end-users and applications providing deep holes from 3.5″ to 6.5″ in diameter at fast drilling rates with low maintenance requirements.

The DCRL130 uses a clean engine that complies with emission regulations (EPA Tier 4 Final / EU Stage V). The “Super Economy Mode PLUS” cutting-edge fuel-saving technology allows the operator to select the engine speed during drilling operations according to rock quality, reducing fuel consumption while maintaining drilling performance. In addition, a compressor with powerful flushing capability and a high-performance dust collector provide high drilling capacity and reduced cycle time. Furthermore, the conventional frame and boom shape have been revised to simplify transportation and maintenance operations.

Proven Versatility

- Bluetooth Player/Sirius XM Radio is standard.

- Angle indicator for quick and easy drilling alignment.

- Drill hole diameter 3.5″ – 6.5″.

- Advanced rotary pipe changer allows easy drill pipe changes.

- High-output compressor increases flushing air, provides faster drilling and decreases bit wear.

Proven Versatility

- Bluetooth Player/Sirius XM Radio is standard.

- Angle indicator for quick and easy drilling alignment.

- Drill hole diameter 3.5″ – 6.5″.

- Advanced rotary pipe changer allows easy drill pipe changes.

- High-output compressor increases flushing air, provides faster drilling and decreases bit wear.

DCRL130 Down-the-Hole-Drill Features & Benefits

- Single-lever drilling control for easy operation.

- Finger-touch levers for smooth traming control.

- Large windows maximize operator visibility.

- All-in-One display allows operator to monitor machine functions and angle indicator for quick and easy drilling alignment while remaining focused on the drilling.

- Walk-around ground level maintenance provides fast, easy upkeep or repair.

- Rubber-mounted engine frame isolates cab from engine vibrations.

- Reliable dust control system increases suction capacity and provides effective pre-cleaning to reduce the escape of drilling dust. An optional dust suppression system is available for difficult drilling conditions.

- Single-lever drilling control for easy operation.

- Finger-touch levers for smooth traming control.

- Large windows maximize operator visibility.

- All-in-One display allows operator to monitor machine functions and angle indicator for quick and easy drilling alignment while remaining focused on the drilling.

- Walk-around ground level maintenance provides fast, easy upkeep or repair.

- Rubber-mounted engine frame isolates cab from engine vibrations.

- Reliable dust control system increases suction capacity and provides effective pre-cleaning to reduce the escape of drilling dust. An optional dust suppression system is available for difficult drilling conditions.

Dependable Blasthole Drills Start at Step One

Blasthole rigs and drills don’t need much explanation. They’re used for drilling a hole into the surface of the rock, packing the hole with explosives and then detonating those explosives in the blasthole to break up rock and hard minerals to make it easier to remove.