About FRD USA

FRD has a rich history in quality manufacturing that dates back to the 1920s. With roots in machining and injection molding, the company morphed by adding a division for pneumatic tool components. This led to the birth of Kent Air Tools, which manufactured its own pneumatically operated handheld tools, like paving breakers, tampers and diggers. Eventually, Kent patented the first reciprocating air hammer, pedestal booms and vibratory plate compactors.

Kent partnered with Furukawa in 1987 to manufacture hydraulic breakers that Furukawa designed. This was the beginning of FRD USA, which came from Furukawa’s purchase of the company, which was now providing rock drills and attachments to the industry.

Since then, FRD USA hasn’t stopped innovating and growing. But, one thing hasn’t changed – its commitment to a quality focus and the best service in the industry.

1924-1929

The C.L. Gougler Machine Company was founded by Charles (Charlie) L. Gougler in 1924 soon after being honorably discharged from the U.S. NAVY where he was trained to be a Machinist.

His original shop was his private garage on Woodard Avenue in Kent, OH. But due to noise complaints from neighbors, he to move to a small facility on North River Road (later to be renamed Gougler Ave.).

Needing to significantly increase production after being awarded several governmental contracts during WWII, the company moved to its current address in 1942 on Lake Street, into a vacant facility previously owned and occupied by Mason Tire & Rubber.

During this time, Gougler Machine employed more than 2,000 people at 10 separate locations around Kent. Their production of specific aircraft and armament parts resulted in winning numerous awards by the armed forces for machining and manufacturing excellence.

1924-1949

Soon after the war, Gougler Machine Company continued to grow by reorganizing into 2-specific divisions:

- Contract Machine Division; machined or assembled per submitted contracts from various outside sources.

- Mold Division; manufactured Plastic Injection Molds for the automotive, military and various other industries.

1957 – 1960

The Kent Air Tool Company was a division born in 1957 to be a reliable supplier of internal parts / components for various manufactures of pneumatically operated handheld tools and originally marketed themselves under the name KATCO.

The Bonnot Company in Canton, OH, a major supplier of extruders to the clay and ceramic industries was acquired by Gougler in 1960. A separate facility was built to accommodate their Sales and Manufacturing. In short time, Bonnot extruders spread into the food, chemical and plastic industries.

1971

With mostly all parts manufactured at Gouglers, Kent Air Tool introduced their own line of pneumatically operated handheld tools. Paving Breakers, Tampers, Diggers, Chippers, Scalers, Vibrators and Pumps were all eventually marketed as GREEN LINE.

1972

With their USA manufactured GREEN LINE being sold through a dealer network, Kent Air Tool introduces RED-LINE, a Japanese manufactured (Toku) full line of hand-held tools that were sold specifically to rental companies.

1973

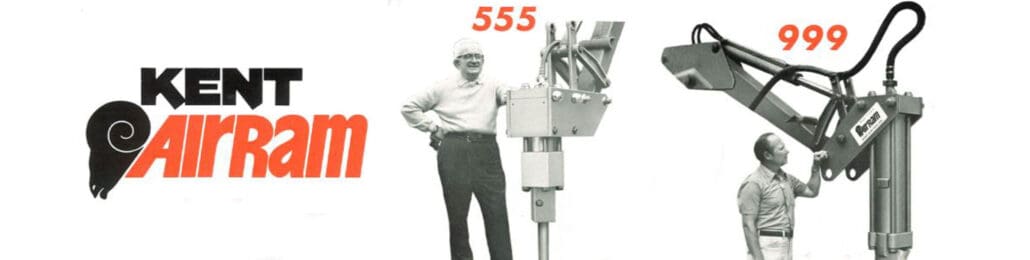

On June 19th, 1973, Kent Air Tool was granted U.S. Patent # 3,739,862 for their “reciprocating air hammer”. Designed by Sam Gunning (gentleman on the left) and manufactured at Gouglers, it was and still is very successfully marketed under the name AirRam. Two sizes were initially manufactured (KB-555 & KB-999) with larger size (KB-2000) added in 1974.

1975

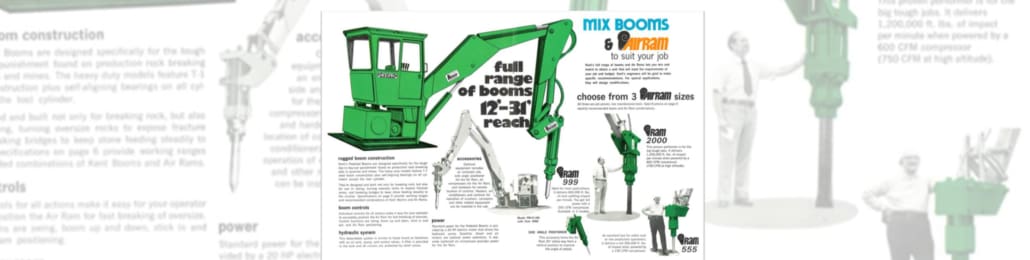

Developed by their engineers and manufactured at Gouglers, Kent Air Tool introduces a full-range of Pedestal Booms (from 12ft reach to 31ft) for quarry/mining and industrial industries. All models are designed to take advantage of all sizes of the very popular AirRams.

1976

Also developed by their engineering department and manufactured at Gouglers, Kent Air Tool introduces 2- sizes of vibratory plate compactors to be marketed as HydraPaks. The KHP-12 was designed for Backhoes while the KHP-25 was engineered expressly for Excavators.

Also in 1976, Kent Air Tool very briefly attempted to market their idea of a “self-contained demolition machine”; the AirRambler. By attaching a KB-999 AirRam to an International 12ft backhoe, powered by a 250 cfm compressor, all mounted to a Loadstar Truck, the enduser was able to quickly drive from one demo job to the next.

1982 – 1984

Recognizing the popular emergence and preference of Hydraulic Breakers (over AIR powered) in the construction sector, but unable to successfully manufacture ‘inhouse’, Kent Air Tool initiated a relationship with Tamrock and briefly marketed two sizes of Hammers; the KHB302 (eventually replaced by the KHB-501) and the KHB901. Poor performance and constant problems with accumulators quickly terminated the relationship.

The relationship with Tamrock was unsuccessful. But, Kent Air Tool firmly believed that the future of ‘boom-mounted’ demolition tools would be those powered by the carrier’s hydraulics. So, the company forged an OEM relationship with the Furukawa Rock Drill Sales Company, Ltd., establishing a marketing territory defined as North, Central & South America.

A full range of six models of Hydraulic Breakers were made available and were marketed as HydraRam. Kent Air Tool quickly realized significant market penetration due to Furukawa’s dependable design and advanced product line.

1987 – 1988

The Kent Air Tool Company changes their name to KENT Demolition Hammers to better reflect their vision of the future.

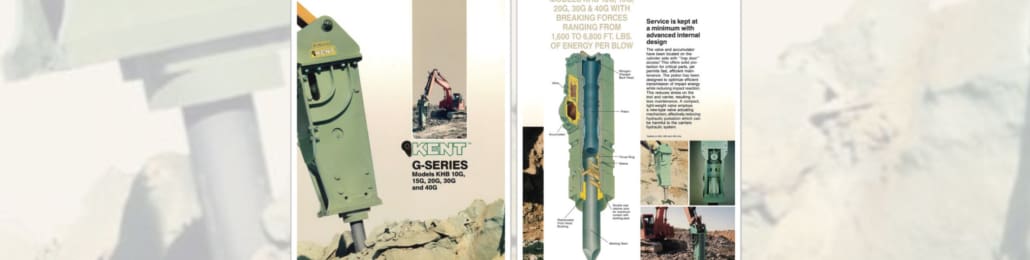

KENT Demolition introduces five large G-Series Breakers designed (by Furukawa) to replace the KHB-700 through KHB1500: KHB-10G KHB-15G KHB-20G KHB-30G KHB-40G.

The name KENT in its distinctive bold font was Trademarked and Registered on November 8th, 1988; No. 1,511,553. KENT’s unique ‘Ram’s-Head’ was Trademarked and Registered on December 6th, 1988; No. 1,515,158.

1990 – 1991

In September, 1990, Furukawa Rock Drill Sales Company purchased Gougler Industries; their Facility, their Property, their Assets & Debt, and 3 of its 4 Divisions. This strategic purchase of Gouglers by Furukawa gave them an anchor location in the Western Hemisphere to continue their pursuit of becoming the ‘market leader’ in boom-mounted hydraulic demolition breakers and to initiate sales of their complete line of Top Hammer Blast Hole Drills (previously marketed in the USA by the Marubeni Group into North and Central America).

KENT Demolition introduces five small/medium G-Series Breakers designed to replace the KHB-100 through KHB-400; KHB-1GII, KHB-2GII, KHB-3GII, KHB-5GII, KHB-8GII.

In 1991 KENT Demolition opens a west-coast warehouse in the Portland, OR vicinity to store & ship whole goods and parts more effectively. They also served as Product Support for all western states. This operation was closed in 2008 during USA’s economic downturn.

1997 – 2001

For the purpose of expanding their manufacturing capabilities, a decision was made by management in Japan to build a 60,000 sq. ft. facility on the southeast corner of the existing shop on Lake Street in Kent, Ohio.

In April, KENT Demolition introduced the full line of F-Series Hydraulic Breakers. This complete redesign replaces the long-running G-Series.

Furukawa introduces their new Tier III Top Hammer Blasthole Drills; HCR 900 HCR 1200 HCR 1500.

In 2001 the difficult decision was made by Furukawa Rock Drill Japan to cease all manufacturing at the Gougler shop and to redefine USA operations as a ‘Sales Subsidiary’ by putting all focus into two newly formed divisions; Rock Drill Division, & Breaker-Attachment Division.

2003 – 2008

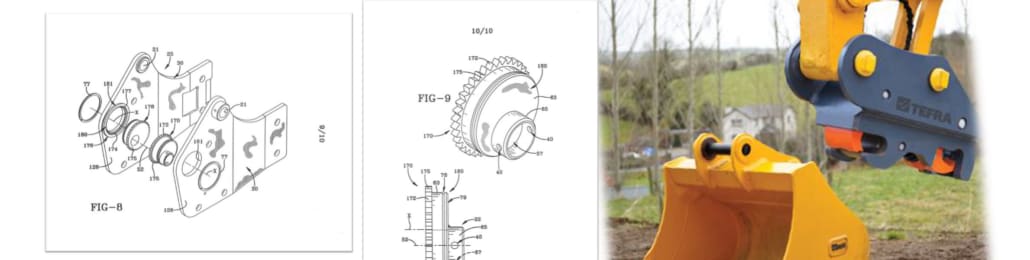

U.S. Patent Number 6,662,681 was assigned to KENT Demolition Tool, Inc. for a “connector assembly for mounting an implement to a prime mover”. This mounting innovation will be marketed a “Switch-Hitch” and is it’s concept is credited to Dan Grznar & Jeff Crane.

In 2005 The Breaker-Attachment Division initiates a relationship with HILL Engineering in Northern Ireland to exclusively market their line of ‘pin-grabbing’ type Quick Couplers. The TEFRA Coupler is recognized as one of safest and most reliable in the industry.

In 2008, Rock Drill Division introduces their new Tier III Down-the-Hole Drill; DCR 20. This drill excels in soft, medium or hard rock conditions and can provide deep holes ranging from 3.5” to 6.5” diameter.

2009 – 2011

South America is removed from FRD USA for the eventual purpose of creating another FRD global subsidiary. Regional responsibility for both divisions is reconfigured.

FRD USA opens their 1st Company Store in Spartanburg, SC for the purpose of direct sales and support into; GA, NC, SC, & VA.

A complete redesign of small size Breakers that eliminates thru-bolts was introduced. The Fx15, Fx25, Fx35, Fx45 & Fx55 replaces the F1 through F5.

2012 – 2016

The vacant Gougler Machine factory and former HQ building is razed.

Following the principles of their previous Fx design that included the elimination of Thru-Bolts and utilizing a Cylinder Liner, the Breaker-Attachment Division introduced 4-large size Breakers. The Fx175, Fx275, Fx375 & Fx475 replacing the F19, F27, F35 & F45.

In 2015, the medium size Fx125 was introduced in two versions (the TLB for backhoes and the Qtv for excavators) to replace the F12. The following year (2016), the Fx225 was introduced to replace the F22. Both the 125 & 225 are designed without Thru-Bolts.

2017-2020

Completing the redesign of FRD’s large size Breakers, the Fx770 was introduced. While it does still incorporate Thru-Bolts, several other improvements are made:

- Larger Diameter Working Steel

- Replaceable Cylinder Liner

- Higher Back-head Pressure to increase impact

- In 2017, the FRD USA Rock Drill Division also began the launch of its Tier IV drills into the North and Central American markets. The product line now includes these top hammer drills: HCR900-ESV, HCR1100-ER, HCR1100-ED, HCR1450-EDII, HCR1800-D20II and HCR11800-D20; and the DCR22 down-the-hole drill.

Our wide range of attachments and drills allow FRD to customize the right equipment for any application.

2021 – Present

To meet the demand that comes with extra-large demolition and quarry jobs, FRD introduced the Fx1070 Qtv in 2022. The breaker works on a wide range of carriers – from 65 tons all the way up to 110 tons – for added versatility. The Fx1070 Qtv replaced the older KF100 breaker, ensuring FRD USA continues to offer a complete line of large series breakers for hard-rock applications.

In the Rock Drill division, most drills now include Tier IV engines to meet strict emissions regulations. Most models are EPA Tier 4 Final / EU Stage V.

The Rock Drill division continues to be an industry pioneer by releasing updated models that deliver innovative features for higher performance, including the ability to continuously adapt to changing rock conditions. Updated model names include the HCRL90 replacing the HCR1450, HCRL110 replacing the HCR1800 and the DCRL130 replacing the DCR22.