A complete line of reliable, cost-effective blasthole and rock drills, hydraulic breakers and rock breaking attachments.

Select a Division Below

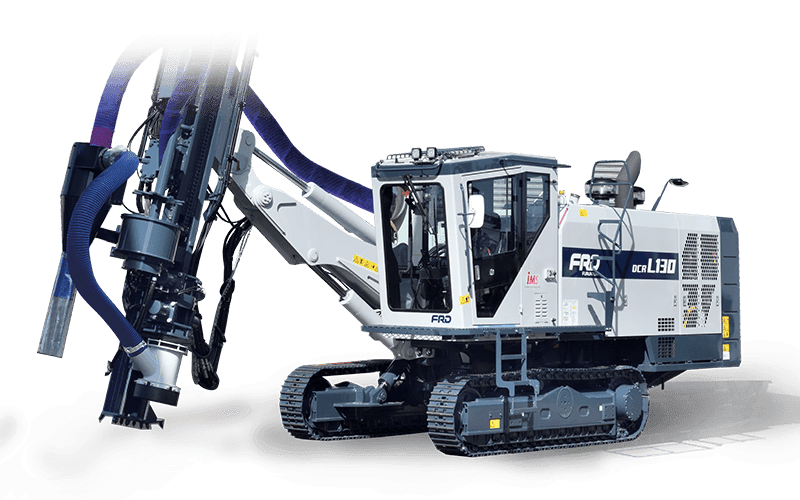

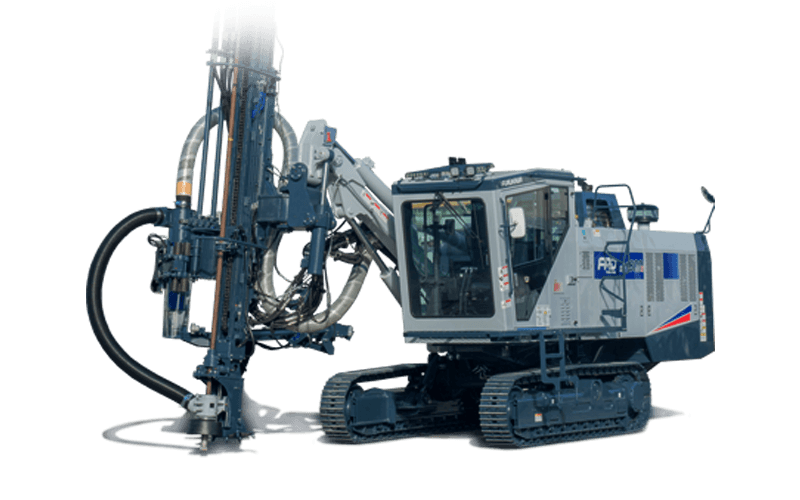

Our Rock Drill Division offers a complete line of blasthole drills and accessories for construction and quarry sites. Our drills are equipped with the latest innovations to ensure reliability, safety and ease of operation, including heavy duty undercarriages, high output compressors and dust collectors, advanced hydraulic and pneumatic systems and comfortable cabs. We constantly innovate to keep up with the needs of the demanding industry.

Our Rock Drill Division offers a complete line of blasthole drills and accessories for construction and quarry sites. Our drills are equipped with the latest innovations to ensure reliability, safety and ease of operation, including heavy duty undercarriages, high output compressors and dust collectors, advanced hydraulic and pneumatic systems and comfortable cabs. We constantly innovate to keep up with the needs of the demanding industry.

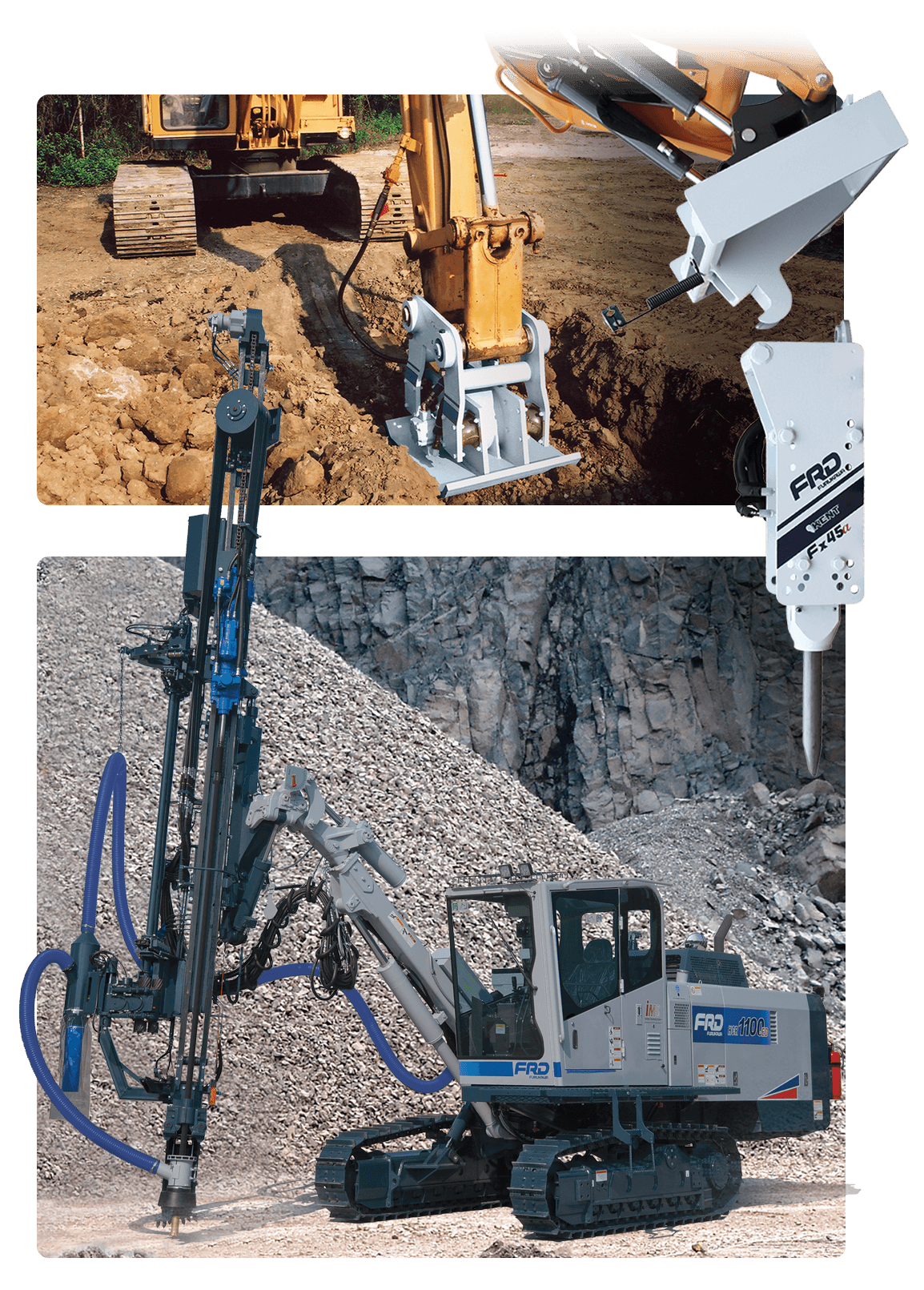

The Breaker and Attachment Division specializes in attachments for compact utility loaders, skid steers, mini excavators, backhoes and excavators.

FRD USA breakers and attachments are built to last. With innovative features such as mono-block body design, the elimination of thru-bolts, improved internal grease routing and patented dust intake prevention systems, our breaker technology represents our ongoing commitment to innovation, durability and quality operation.

Leading Innovations for Construction, Mining and Industrial Applications

Furukawa Rock Drill (FRD) USA is a leading manufacturer of blasthole drills, breakers and other attachments for compact utility loaders, skid steers, mini excavators, backhoes and excavators.

FRD USA is a wholly owned subsidiary of FURUKAWA ROCK DRILL CO., LTD., founded in 1875 by Ichibei Furukawa to mine and smelt copper. FURUKAWA has diversified over the years to become a leading corporation in Japan. Today, in addition to mining, FURUKAWA also has business in machinery, metals, electronic materials, chemicals and real estate.

FRD USA operates two divisions in North and Central America, with headquarters in Kent, Ohio, a full-service facility in Spartanburg, South Carolina and a facility in Reno, Nevada. As a technology company, our products are always on the leading edge, incorporating all the latest equipment advancements to increase reliability, ease of operation and safety.